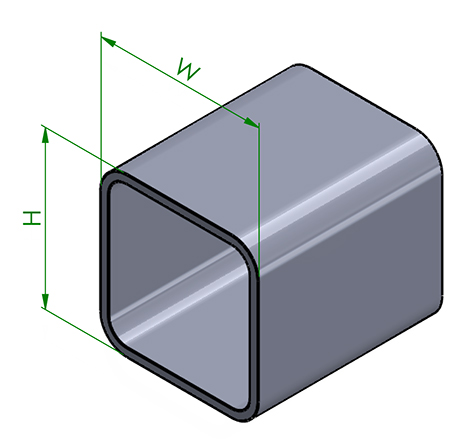

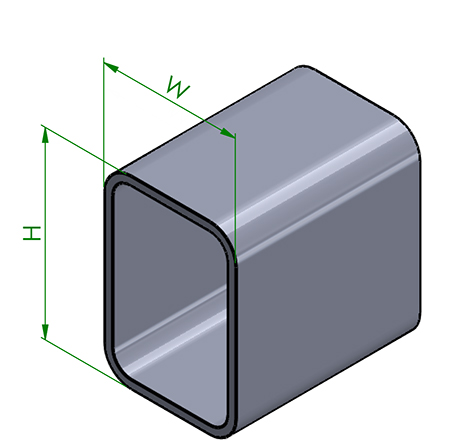

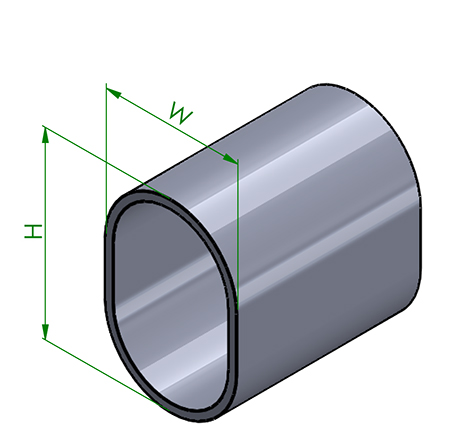

Formed Tubing & Extrusion

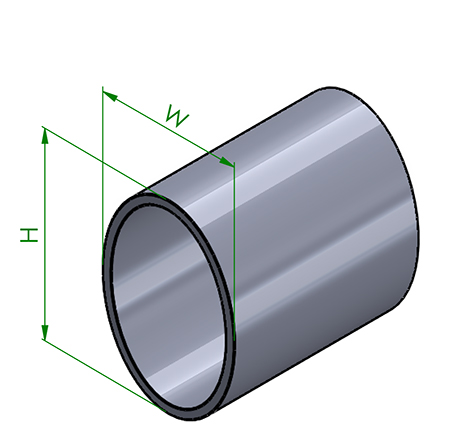

Shaped tubing, particularly with a fixed cross-sectional profile, has its advantages for meeting various applications. Unlike the standard round shape, square or rectangular tubing can increase strength or stiffness against bending. Polygons are great for mounting and positioning, while ovals and airfoils are excellent for aerodynamics. We are able to provide shaped tubing in all our stock alloys in either plain gauge at various lengths or butted configurations up to 750mm tube lengths. Below are popular shapes we mechanically form or extrude.

Similar to the production method of aluminum barstock and round tubes, we can also provide custom extrusions for various industry and manufacturing needs. Extrusion is a process where raw alloy is pushed through the opening(s) of a die to produce a desired shape with a fixed cross-section. This process results in elongated pieces of consistently shaped aluminum. Extrusions can also have a variety of hollow sections, which is advantageous for mass-producing parts or materials. Temperatures are regulated from the heating to the cooling processes to ensure desired properties, then artificially aged to achieve proper temper or hardness. Contact us for questions or inquiries regarding shaped tubing and custom extrusions.